FSCM’s secret weapon helps identify impact of purchase order changes

Managing purchase orders can be the biggest headache ever, especially with all the current supply chain disruptions. Whether you’re a small business owner or part of a large corporation, the purchase order process is essential. However, it’s also a time-consuming process that’s prone to errors.

Boyer & Associates has a better way thanks to Copilot support for procurement. With the use of modern AI technology in Microsoft Dynamics 365 Finance & Supply Chain Management, you can streamline this process and make it more efficient.

We have helped numerous businesses transform their purchase order process with Microsoft AI technology. Read on and find out why incorporating AI into your purchase order process is a game-changer.

Challenges of manual purchase order process

Before we dive into the specifics of AI, let’s look closer at what purchase orders are. A purchase order (PO) is a document sent from a buyer to a supplier indicating the products or services they wish to purchase. It contains details like the type of product, quantity, price, and delivery dates. Essentially, it’s a legal offer to buy something.

Many of our clients come to us still relying on manual processes to fulfill their purchase orders. They have multiple steps, including creating the PO, sending it to the supplier, tracking the order, receiving the goods, and finally, processing payments. One of the ways Boyer & Associates helps is to automate these processes through Microsoft solutions.

Manual PO processes are:

- Time-consuming: Manually creating and sending purchase orders takes up valuable time.

- Error-prone: Human errors, such as typos or incorrect data entry, can lead to costly mistakes and delays.

- Limited in visibility: Tracking and managing purchase orders manually makes it difficult to get a real-time view of the order status.

- Inefficient: Manual PO processes usually require a full-time employee and are inherently less efficient. This leads to longer processing times and increased operational costs.

How AI can help

Artificial Intelligence (AI) can drastically improve your purchase order process by automating many of the tasks that are traditionally done manually. First, AI technology can help automate one of the most tedious aspects of purchase orders — data entry. It can extract PO information from your emails, PDFs, or other documents and put it into the appropriate fields. This not only speeds up the process but also reduces the risk of human error.

Second, AI-powered systems can give you real-time updates on the status of purchase orders. This means you can track the progress of your order from creation to delivery without having to manually check and update statuses. This type of improved visibility trickles through the entire organization, helping with better decision-making and planning.

Additionally, using Copilot support for procurement the system can match purchase orders with invoices and goods received. This ensures that everything aligns before payments are processed. This reduces the chances of discrepancies and makes the reconciliation process much smoother.

Boyer & Associates has found that one of the most powerful features of AI for our clients is its ability to analyze data and make predictions. In the context of purchase orders, AI can predict demand, optimize inventory levels, and even suggest the best times to place orders. This proactive approach can save businesses significant amounts of money and resources.

With this automation technology in place, businesses reap increased efficiency, better accuracy, enhanced visibility, and cost savings.

What is Copilot support for procurement?

If you’ve been wishing that you could head off procurement problems before they happen, there’s good news with Microsoft Copilot’s support for procurement. This tool empowers users to manage and assess changes to purchase orders on a large scale. By providing insights into the impact and risk associated with these changes, it greatly enhances procurement decision-making. Identify high-impact or low-impact alterations, so you can take action and avoid messy problems.

The technology behind Copilot support for procurement offers a concise overview of purchase order modifications, including adjustments in quantities and delivery dates. It also highlights any potential downstream effects that may arise from these changes. Copilot generates natural-language summaries of these modifications, making it easier to understand and communicate their implications.

Supply Chain Management Copilot in action

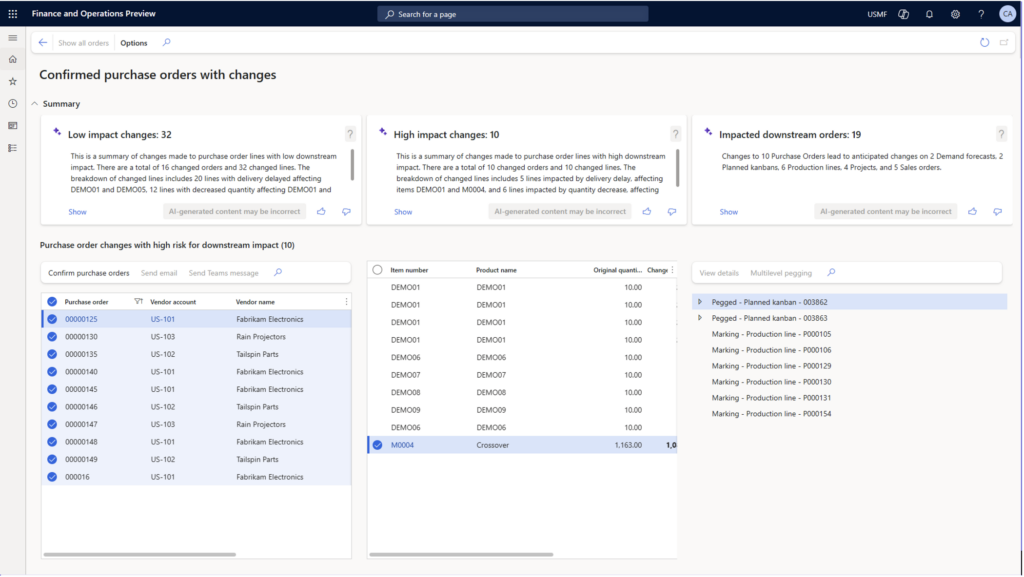

Confirmed Purchase Orders with Changes

The “Confirmed Purchase Orders with Changes” workspace will change your life. Seriously, we are not kidding. This new tool is particularly valuable as it makes it easy to identify changes that have minimal downstream impact. Procurement managers can efficiently focus their attention on high-impact changes, paying attention to their effects on downstream orders. It opens the opportunity to communicate with vendors to address any potential issues before they become nightmares. Overall, this comprehensive set of features helps optimize the entire procurement process and improves collaboration between stakeholders.

To open the workspace, go to:

Workspaces > Confirmed purchase orders with changes.

The workspace here lists all previously confirmed purchase orders that have been changed since confirmation. It helps the review process by identifying potential impacts on production work, service work orders, and sales orders.

Three tiles at the top of the workspace summarize groups of changes to purchase orders and their downstream impacts.

- Low-impact changes – This tile highlights changes to purchase orders that have no known impact on downstream orders. A summary of changes is generated to help you review and validate the purchase orders.

- High-impact changes – This tile highlights purchase orders that have known downstream impacts on orders. These high-risk changes are summarized together with the detected impacts, to help you investigate further and decide what action to take.

- Impacted downstream orders – This tile summarizes impacts on orders by the number and type, and it shows the purchase order changes that cause each impact.

Each tile provides a “Show” link, which lets you filter the list of purchase orders and purchase order lines. The list includes columns for the original and new quantities, original and new confirmed delivery dates, and more.

Review changes to confirmed purchase orders

Purchasers use the workspace to review and accept changes to confirmed purchase orders. They typically follow these steps:

- Study all changes to confirmed purchase orders and their downstream impact.

- Focus on changes that have a low risk of downstream impact.

- Review changes that have a high risk of downstream impact.

- Review the remaining downstream impact.

Below are those steps in more detail …

Step 1: Study all changes to confirmed purchase orders and their downstream impact.

Start by opening the Confirmed purchase orders with changes workspace and look through all the changes that have been submitted through the purchase order change management process.

When a purchase order that was previously confirmed is changed, it’s moved back to the Approved state. The workspace shows all purchase orders that have been changed after confirmation.

The workspace shows two lists: one for the purchase orders and one for the purchase order lines.

The purchase order list shows the purchase order number, the vendor, and the requested receipt date from the purchase order header. To view the related records, select the purchase order or vendor link in the list.

The purchase order lines list shows information about each line that has proposed changes. This information includes the item number, product name, original quantity, new quantity, original confirmed delivery date, and new confirmed delivery date. The workspace also provides a hierarchical view of any downstream impact. The Reference field indicates the type of downstream impact, such as a planned kanban for a production order, a sales order, or a maintenance work order.

Step 2: Focus on changes that have a low risk of downstream impact.

Most folks typically start by focusing on low-impact changes. These changes have no known downstream impact according to the current plan.

The low-impact changes tile at the top of the workspace provides an AI-generated, natural-language summary of the changes that have a low risk of impact. Select the “Show “ link to open the corresponding filtered view.

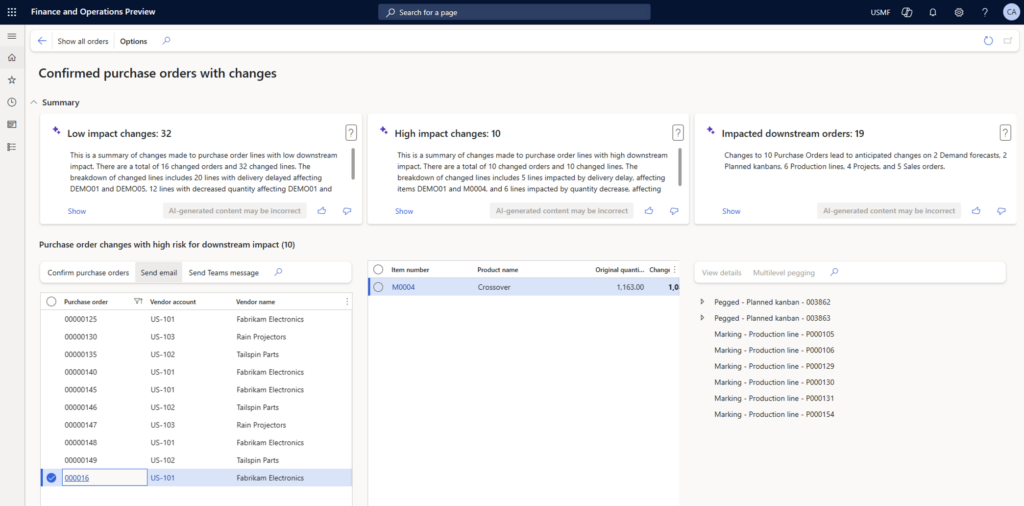

Then review these changes and accept them by selecting individual or multiple purchase orders and then selecting Confirm purchase orders on the toolbar. The procedure for confirming the changes is the same as the procedure for confirming a purchase order for the first time.

After the selected purchase orders are reconfirmed, they’re moved back to the Confirmed state.

Step 3: Review changes that have a high risk of downstream impact.

Now it is time to spend the bulk of your time on changes that have a high risk of downstream impact. These changes have downstream orders allocated to them, and the downstream impact has been identified.

As in the steps above, you can click the “Show” link to open your filtered view and study the impacts and determine which actions to take.

From this view, you can reach out to a vendor using email or Microsoft Teams. Using the contact details of the vendor contact person, the system generates a proposed message text and adds it to a new email message or Microsoft Teams chat. You can then review, update, and send the message. It’s a very intuitive and easy-to-use feature.

After you’ve communicated with the vendor, you can update the order further and then send it back to the vendor for confirmation. Alternatively, you might cancel the order and plan for alternative supply.

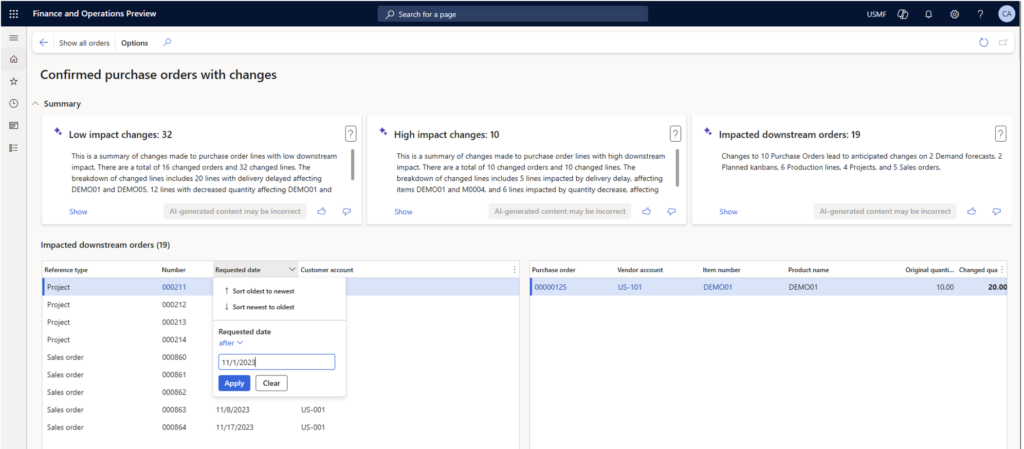

Step 4: Review the remaining downstream impact.

After most of the order changes have been addressed, you can review the overall downstream impact of the remaining open order changes.

The Impacted downstream orders tile provides a summary of the downstream impact. Select the “Show” link to open a filtered view where you can focus on those impacts and act.

In this view, you can analyze the changes from the perspective of downstream impact and identify the purchase order changes that are causing the impact. You can then take action on those purchase orders.

A good way to focus on the most pressing downstream impact is to sort and filter the list by the date of impact (the requested date in the downstream order). You can then take action by communicating with downstream stakeholders. Those stakeholders might, in turn, contact affected customers and replan the downstream orders.

Ready to get Copilot support for procurement?

Microsoft’s Copilot support for procurement in Dynamics 365 Supply Chain Management (phew, that’s a mouthful) offers a powerful and intelligent solution to address the challenges of managing purchase order changes. It is so much easier and faster than doing it manually. We can’t imagine going back to manual processes. The tool gives you and your team the power to efficiently assess and manage changes, identifying high-impact alterations and streamlining collaboration with vendors. It truly optimizes procurement, which leads to a more agile and responsive supply chain.

Contact Boyer & Associates to learn more about the power of Copilot tools available to streamline your business processes.